Thanks, all! I’ll see if my local hardware (not a big box store - against the norms for today) has the correct ~3/4" bolt for this face plate. If not maybe the 1" bolt I have can be cut…for the best fit possible.

The machine screws used to attach electrical faceplates use a 6-32 thread, and usually a slotted oval head type, though Philips flat head will work just fine as well. Many electrician’s pliers have a pair of offset holes near the pivot that are designed to shear off a 6-32 screw to desired length. Your local hardware store dude, or dudess, would probably let you test one to ‘see how it works’ for the one screw you want to shorten, if they don’t have a shorter one in stock already.

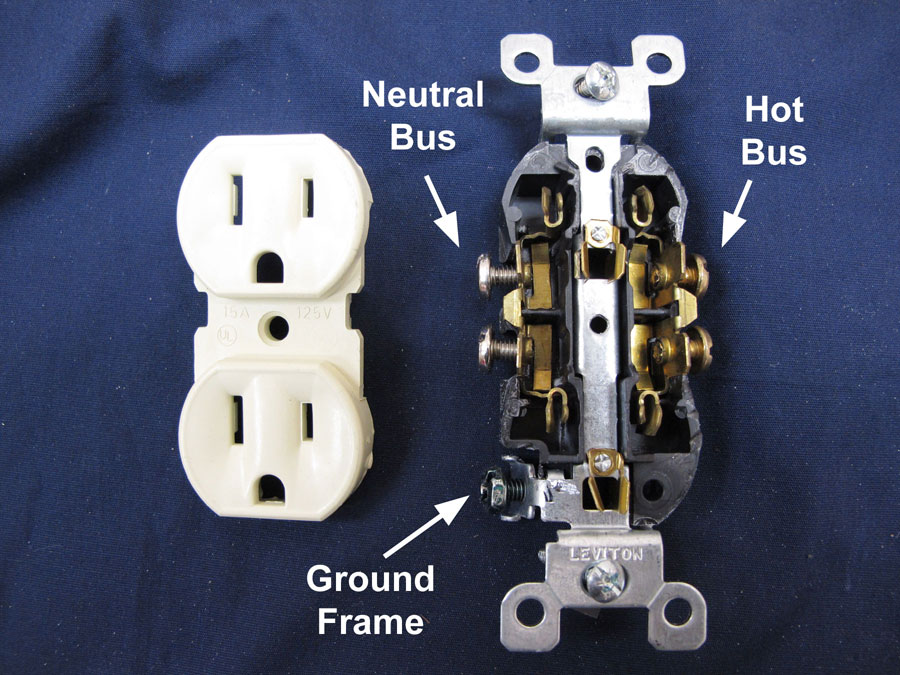

In case you are wondering what is inside your electrical outlets, they usually look something like this:

The screw that holds the faceplate on goes into the screw hole on the metal frame, which is connected to the ground terminal on the outlet. That’s intentional. The screw in the center of the faceplate is connected to electrical ground. If you have ever used a 3 prong adapter, you may have noticed that they have a little metal tab sticking up.

The basic idea is that you take out the screw in the faceplate, insert the adapter, then put the screw back into the faceplate so that it goes through the hole in that tab on the 3 prong adapter.

Like so:

I have never seen anyone actually do that. People just plug them in and that’s it. But, that’s what they are there for.

The metal frame of the outlet also physically contacts the electrical box that the outlet sits in, as well as being screwed to it. This provides a solid ground connection to the electrical box, if it’s a metal box. Some boxes are plastic.

Again, all of this is intentional. As long as your outlet is wired correctly, it’s safe to touch the screw. The metal bit that the screw goes into is part of the safety ground system for your house.

There’s usually a bit of space behind the metal frame, so you can use a slightly longer screw and it won’t cause a problem, but if you use too long of a screw to hold the faceplate on, you risk poking the screw through the plastic case of the outlet and breaking it (unless you have one of those industrial outlets for some weird reason - you typically don’t see those in a house).

Your 1 inch screw is probably too long and risks damaging the outlet.

They usually use slotted screws for aesthetic reasons. Using a Phillips will work just fine, but some folks will think it looks funny.

As @vbob said, they use 6-32 thread screws, which is a very common screw size. Ye ol local hardware store should have bunches of them in various lengths. Take the outlet cover in and use one of the hardware store’s outlets to test the screw length.

Yep. Here’s a tip, though: thread a nut onto the screw before cutting the screw. Cut screw, then remove nut. The process of removing the nut will help clean (dress) the threads at the end of the screw.

Those pliers have a built-in screw thread.

You screw the screw in to the right depth, cut it, then unscrew it.

Ah, you’re correct. ![]() I was thinking of the case when you’re cutting it with a hacksaw.

I was thinking of the case when you’re cutting it with a hacksaw.

I’ve always thought that feature was dumb, because in every case I’ve ever personally experienced, the reason one needed an adapter was because there was no ground in the box to begin with. Thus, this feature is useless.

Of course, I understand there are cases where ground is present, but only a two prong outlet was installed, but by now I think the vast majority of those were replaced with grounded outlets.

My folk’s house was built in the narrow timeframe where this was possible - they had 2-prong outlets, but the power was run in “BX”, which ended up being grounded. Soon after that, everyone switched to 2-conductor Romex, so it wasn’t possible to ground to the box.

I just added grounds to all the outlets in our summer house, which was built in ’59. I had to drop ground wires into the crawlspace, and run a ground net to all the outlet locations.