I’d have to point out that SpaceX is actually saving money as its cost is what? Half that of the competitors? And actually delivers. Those payloads need to go up - the number of ISS flights is minimal compared to actual commercial flights. Copanies pay for the flights because the result makes money for them in the long run.

And - that’s the model for any space work. There will be trailblazers - like Apollo, Mir, Tiangong and ISS - that are profit-proof but proof of concept, followed by increasingly proven lucrative endeavours.

But I do have to say that you match one of my criticisms - I’ve seen a lot of hype on getting the biggest rocket ever to launch the biggest ship ever into orbit, but not a lot on what goes inside that to let people live for years on a trip to Mars and back.

Burrowing into an asteroid - ignores the point that if you can’t practically disturb it without it falling apart, how do you put it into a practical orbit? Not to mention, the rocket fuel needed. Not to mention, how much fuel is needed if we start bringing material in from the asteriod belt and other points outer? There’s a reason cycle orbits are recommended over just pointing the rocket to Mars and firing all the way.

I will agree, the supply chains here are complex, because they can be. If it’s cheaper to run a factory in Vietnam or Thailand, and ship half-way around the world, that’s what we do. If it’s cheaper to have 20 different screws in a product, or pick one of 500 electric motors for an appliance, they do - because those are available. My battery-operated hand drill is far far better than the corded one I owned decades ago, but in all practicality not worth repairing. Same for the batteries (Ryobi) half of which despite tricks cannot be revived. Inside, the cells are soldered together.

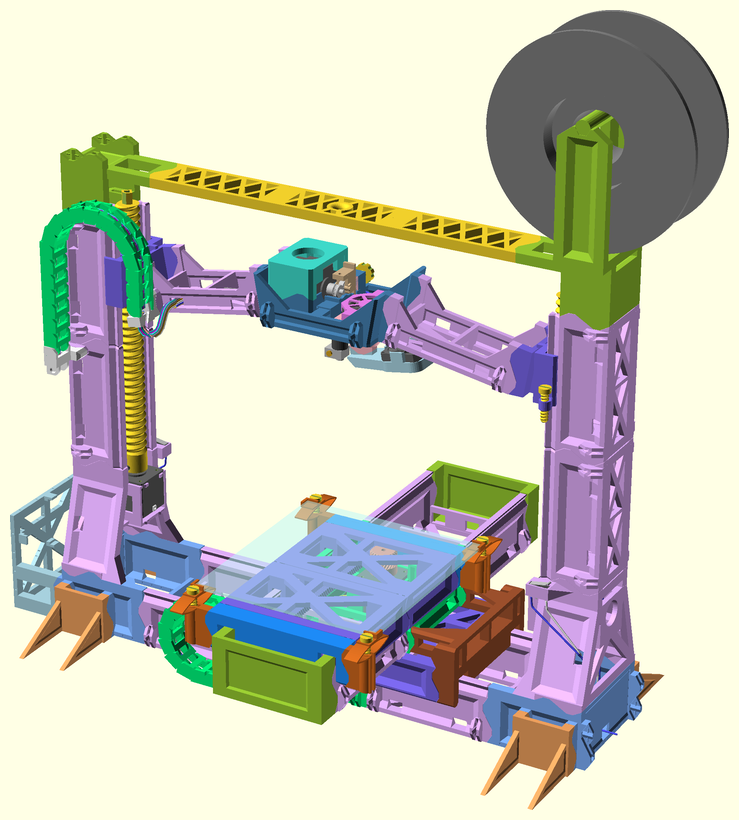

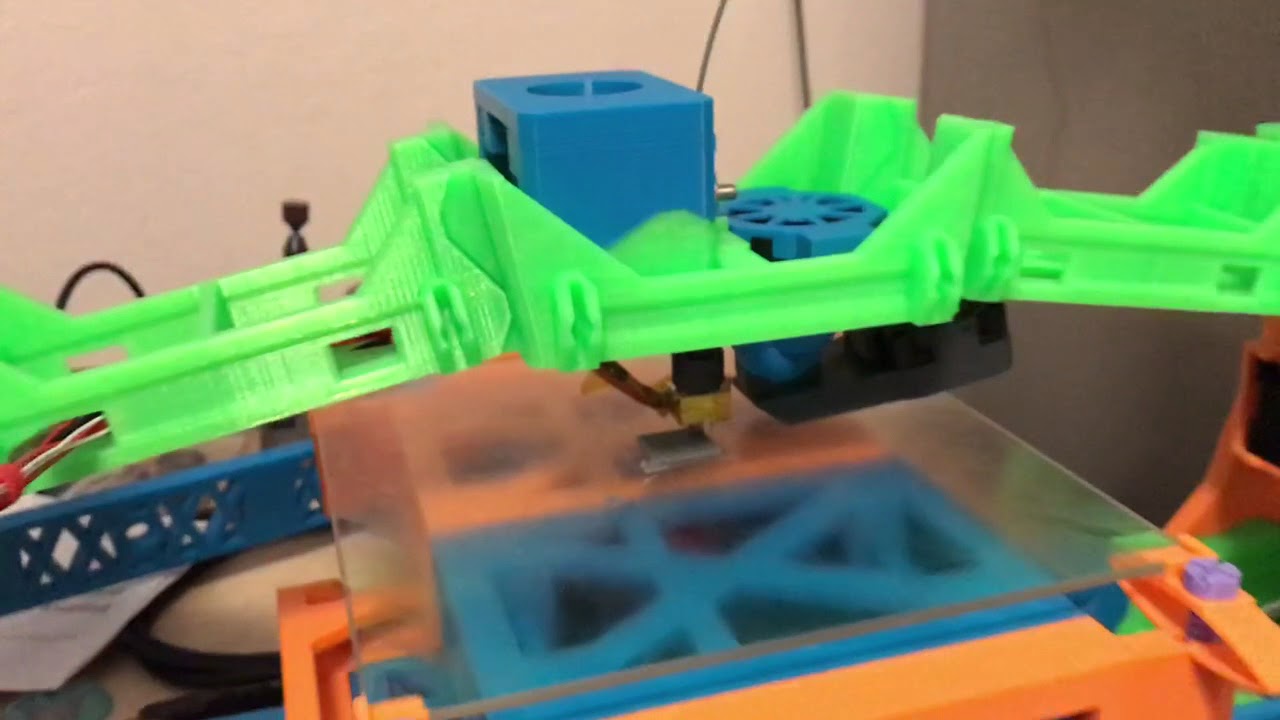

First, computer chips seem to be the lightest, most practical things to actually import until a colony is fully robust; I see more that things like screws, wire, sheet metal, bearings, seals, molding and forming equipment, metal refinining and processing, etc. are more practical things to not only make on site, but build progressively more and larger versions of the fabrication plants. The start point is a 3D printer, which then makes rough-and-ready fabrication plant parts, etc. For self-driving mining machines, you’ll repair the moving parts far more often than the electronics, and they are the bulky high-weight parts you are better off making locally - and can start as lower-tech parts. In practicality, it’s a boot-strap process.

The point about simplified parts is key. I recently assembled a new barbeque - it came with a dozen difference bolt sizes - if it were more important to minimize the number of parts, or live with bolts where the end sticks out an inch to minimize variation, that can be engineered. Instead, it was engineered for aesthetics. Colonoists will at first skip that luxury.

Yes, a colony in space will be more regulated and monitored than any authoritarian society on earth. The guy who loses touch with reality on earth takes an AR15 (assuming they are American) and shoots a dozen people. Someone who slips a cog in a space habitat has the potential to kill 50% to 100% of the population and/or doom the rest. By then, I assume AI will fill in the role of the Future Crime committee, warning the colony politburo when someone shows signs of erratic behaviour or insufficient dedication to the cause.