Most suburban homes have a driveway that slopes downward toward the street, so if concrete were leveled by gravity, then most suburban homeowners wouldn’t be able to have a concrete driveway. There are limits, of course - you can’t sculpt wet concrete into a 20-foot tall wall and expect it to stay vertical - but it definitely doesn’t flow like water.

Wikipedia says the earth’s curvature was “taken in to account”, but it doesn’t say how, and there’s no cite, so I’m dubious. Assuming each of the two main support towers were independently constructed to local level, then the earth’s curvature wasn’t “taken into account” any more than it was for two unrelated buildings on the opposite sides of Manhattan. While the earth’s curvature definitely manifests in the extra distance between the tops of the towers, the only way I could think of that could actually matter WRT the design of the bridge would be the length of the main support cables, but we’re talking about an extra 1.625 inches on a main span of 51,120 inches. The seasonal thermal expansion/contraction of the cables is far greater than that.

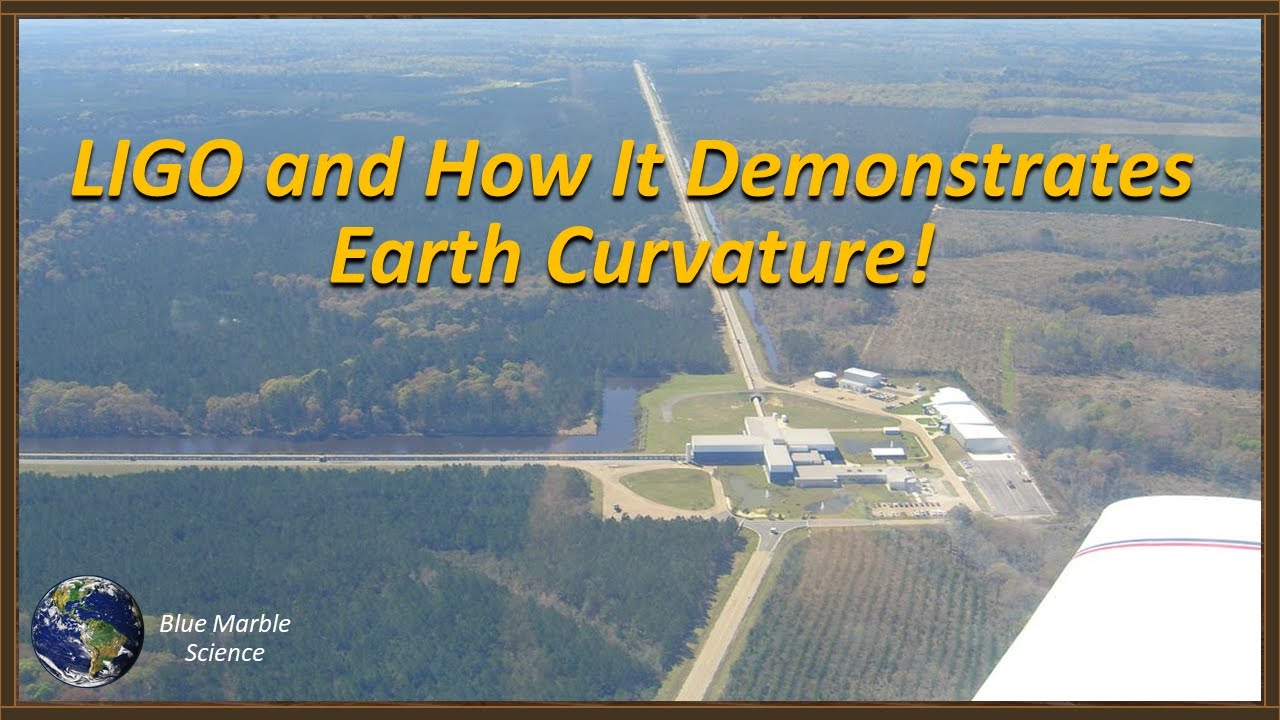

The OP’s question was about whether there are actual cases for which it’s not negligible, i.e. do real-world architects and civil engineers have to consider the earth’s curvature when designing large structures. Respondents have shown that there are esoteric physics projects (e.g. SLAC, LIGO) with straightness requirements over long distances that can’t be met by following the earth’s curvature, but for even the largest conventional civil engineering projects - that is, structures on the order of 1000 feet tall and a mile long - I don’t think we can point to a project where it matters.

Part of the issue is that civil structures are generally made of individual components (e.g. steel beams) that are much smaller than the large dimensions under consideration here, and each component comes with its own shape tolerance, size tolerance, and installation tolerance. Taking the OP’s example, the Tesla factory probably will be made with steel columns on the order of 50 feet tall and maybe 100 feet apart. At that distance and size, the deviation from parallel between any two adjacent locally-vertical columns is 0.00027 degrees. According to this site on standard erection tolerances (hold your jokes), a 50’ tall column would be allowed to be off-plumb by 1 inch at its top, a deviation from local vertical of 0.191 degrees. Steel beams and trusses are imperfectly shaped/sized, bolt holes are imperfectly positioned, and all are imperfectly installed at the construction site. The allowed imperfections are hundreds of times greater than the deviations from rectilinear imposed by the earth’s curvature and are compensated for with oversized holes, shims, and lots of pounding and pulling by steelworkers to get it all put together. If you’re building a shopping mall or a battery factory, the errors introduced by the earth’s curvature get lost in the noise.

Edit: and now that I’ve said all that, here’s a case where the earth’s curvature did matter: