A brief animation of the repair:

Did they ever say if they had inspected the rest of the bridge structure for additional cracks? Looks to me that using a drone to do a first pass to find areas of interest would be a workable solution for lots of structures, not just that bridge.

Looking at that, all I can think is that they were incredibly lucky that beam didn’t break before someone noticed the crack.

From the ENR article I cited above:

Meanwhile, Michael Baker International and HNTB are conducting in-depth inspections of the bridge arch and superstructure to ensure no other existing or potential faults were missed during previous assessments. Ultrasonic testing is being used to examine all welds in the main tie girder at locations similar to that of the fracture location, as well as on key members of the overhead truss. That process is expected to take four weeks to complete.

Well, this is a good time to perform a comprehensive inspection. Make sure there’s no further problems after the bridge reopens.

Hopefully this makes officials realize the need to prioritize building another bridge across the river. There’s too much heavy truck traffic. The FedEx hub added a lot of trucks to the existing roads.

Steady progress.

The thread on the engineering board has a photo of one weldment/anchor installed. https://www.fox13memphis.com/bridgeshutdown/tdot-says-contractors-make-significant-progress-i-40-bridge/GDOA5HSL3REPDFEE2DCUP63KWY/

A reporter’s experience driving across the bridge:

Emergency services is a major concern. They’re having to take emergency patients to smaller hospitals in Arkansas. The ambulance can’t get into Memphis quickly enough.

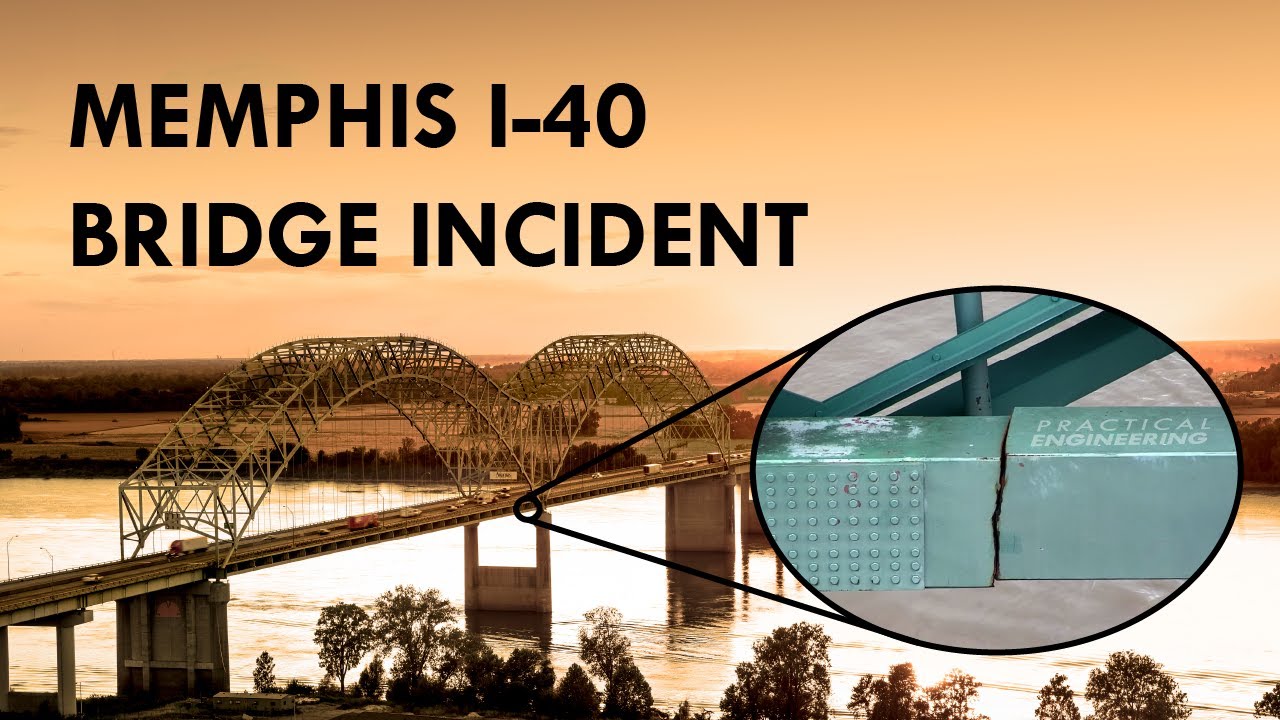

For those interested, Practical Engineering has a good video about the problem and a good explanation of the stresses on that beam (on that type of bridge). I especially liked his comment about them firing one guy over missing the crack. [Paraphrased] If your inspection fails over a single person’s mistake, there’s something wrong with the methodology and firing “1 guy” isn’t going to correct the systemic problems.

His bow string explanation is very good. I didn’t realize how much tension is on that beam. Imagine cutting a tight bow string. The bow would instantly straighten and smack your face.

I understand now why the inspection team immediately dialed 911.

Quick question.

The threaded rods that will be used in this repair. Are they planning on pulling the ends of the arch inwards? Restoring the tension in the repaired beam?

This is really key in everything we do in our complicated world.

Humans goof, but any system that isn’t designed to operate with nil defects despite the goofs by detecting all goofs and covering for all their consequences is inherently defective itself.

Obviously “nil” and “all” are qualitative measures, not 0% and 100%. And acceptable values of “close enough to nil/all” will vary depending on whether you’re assembling a sandwich or a bridge.

I saw that last night and was a bit disappointed that you best me to posting it.

But yeah he does a great job of explaining what happened, to the best of his knowledge.

I also like that he explains what the limits of his knowledge are, and what is speculation that will not be confirmed (or dismissed) until a formal analysis is done.

Given all that, I’m actually surprised that the bridge hadn’t already collapsed.

Does depend a bit on what it was as to whether there would be a single point of failure. If the guy involved put in paperwork saying that he had hired an inspection team, but instead pocketed the money and submitted false reports, then I could see how that could have caused this to be overlooked.

However, that’s not a mistake, that’s fraud. If there is a single point of failure here, it seems it would almost certainly be something that someone should lose a whole lot more than just their job.

Given that you could see this crack from the river years ago, I can’t understand why it was missed.

Whenever a freshly-landed space shuttle was being turned around for its next mission, NASA had teams of workers inspecting and refurbishing the orbiter. AIUI, they really did work in teams, to make it harder for any one person to slack off. And then a team of inspectors would go over the whole thing to verify that it was ready for its next flight. And then a second team of different inspectors would repeat that inspection. It wasn’t exactly like that, but you can see the intent: NASA tried to make it very difficult for any single person’s mistake or negligence to bring down an orbiter. If you know the details of how Challenger and Columbia were lost then you know the system wasn’t perfect - but if the orbiter inspection process went more like that of the de Soto bridge, we probably would have lost a few more orbiters (or just cancelled the whole STS program much sooner).

That’s my understanding, though I don’t think it’s a matter of noticeably pulling the ends of the arch inwards. Right now, those forces are lateral forces on the piers, which were not built to resist them. Post tensioning rods will be tightened to restore the forces to the beam, then the patch plates will be attached to hold the forces there as tension on the beam.

Had the piers not been strong enough to resist the unintended lateral forces that were transferred to them, the bridge would have collapsed. I wonder how much thought is being given to the effects on the piers of having held those lateral forces. I would think they need careful inspection now, and after the repair.

Wouldn’t it not just be the piers, but the roadway on either side as well that would have been taking up the tension of the failed beam?

Not sure if that’s better or worse.

I don’t think that the roadway is attached in a way that would do that. That’s based on a vague memory of what I read on the eng-tips site a while ago, though. And I don’t think the roadway could take those tension forces. Those materials are not strong in tension.

But, if I’m wrong on all that, the same would go for checking out the roadway, or wherever the forces wound up.

And that’s my concern, it’s not really made for it, and yet, may have been subjected to some of those forces, compounding the damage.

But if it’s actually isolated in a way that it wouldn’t have been transferred, at least there’s that.

They’re even temporarily removing the floor beam stiffeners. I assume so they can better tension the repaired plate.

It may be a major PITA to reinstall the deck stiffeners. A small alignment change could mean bolts won’t align. It can be done with the right tools and lots of swearing.

Has the root cause been reported? That is, why that beam was over-tensioned?

They won’t be able to say for sure until an exhaustive investigation is completed. For theories watch the video Pullin cites a few posts previously.

It hasn’t collapsed because the ‘bow string explanation’ isn’t very good. That bridge has a rigid arch, not a bow stave.

I keep waiting for somebody to publish actual analysis, instead of saying “we’ll have to wait for analysis”, but on simple observation, the primary function of that member is to stiffen the structure. It doesn’t look like a tension member. It didn’t crack like a tension member. It didn’t fail like a tension member.

The road is supported by strong cross members supported on strings. They would naturally tend to sway independently, which would bounce the traffic, tear the road apart, and sing in the wind. The cross members are tied together by a stiff box girder on either side, to prevent those modes of failure.