I also have some engines that I can’t show you. Would you like to not see videos of those too?

To be fair, it’s not a perpetual motion machine, if that’s what you’re thinking. Those blue arrows presumably represent wind, pulling the water up the columns.

There was a two-stroke engine design I saw online a few years back, which had pistons in pairs, with the four strokes of a four stroke engine divided between the two pistons. One piston produced power each stroke, and the other piston was responsible for compressing the air-fuel mixture before passing it the first piston. The author/inventor claimed some kind of thermodynamic efficiency because the compression piston didn’t get as hot as the power piston. Maybe the power piston could stay hotter to extract more useful energy from each explosion, I don’t recall exactly.

Anyone else ever see this, who can comment on whether there’s any possible benefit there?

Are you talking about the Twingle?

Good point. Those chordons (flappy things) are going to get very hot. They are going to have exhaust gasses on both sides and passing through them. Oil jets won’t work because the back of the chordons is not in a separate crankcase like the back of a piston is. All the oil would be blown out the exhaust.

I also notice that the swept area of the chordons is a very large percentage of the chamber’s area. This would seem to cause some seriouse pumping action within the chamber. Exhaust gasses are going to be getting pumped in and out behind the chordons. Traditional two strokes use the pumping action of the piston to pressurize the air in the case, and this pressurized air is forced into the combustion chamber. The IRIS design seems to waste that energy.

o Yes, this was an important step…

http://home.sprynet.com/~inniss/sears.htm

Here, the photo of the engine and Abart, for those who have doubts about the hight engine of my…

Andrew:)

Wait just a gosh darned minute! You mean all engines don’t run at Carnot efficiency!? :eek:

![]()

Not only that, but they can’t even run at Car-nut efficiency!

(That is, their motion is less efficient than the flapping of a car-nut’s jaws while he talks up the good points of his favored design.)

A little about the efficiency of engines…:rolleyes:

So interesting what you can find in my archives. The oldest Radioamator I found in my …

Google translated :

“According to information published in one of the writings of English - has been developed by researchers at the concept of electricity generation by passage of ions and electrons with very high speed through a magnetic field

The practical implementation of this method that was based on Plasma gas forcing by the strong magnetic field. Electrical power of 1000 KW can be obtained by passing the said plasma at 3 times the speed of sound, the magnetic field of 1 meter long between the poles of a magnet at a distance from each other by about 15 cm. No, you would need the boilers and steam turbines. Previous experiments have generated so far a small amount of electrical energy. Achieving the full effect expected after several years of further intensive tests conducted”…

Maybe the exhaust manifold to the F1 wear a magnet and additional energy (electricity) have?

Do not give me those numbers alone … When linearly decreased as the amount of energy … it

5 cm in diameter and 1 meter length of pipe that is 10 times less that is = 100 KW

The flow rate is not 900 m / s just say 200 m / s that is to say 4, 5 fold less = 22KW … For each cylinder?

How can I bypass the statutory 20 mm in diameter … and we have a little more air in the engine intake manifold

http://sae.wsu.edu/media/0708car/08-03-10/

http://sae.wsu.edu/media/0708car/08-03-10/images/IMG_3301.jpg

And here, if the exhaust pipe wrap neodymium magnets … I have a small MHD…

http://sae.wsu.edu/media/engine/target0.html

http://sae.wsu.edu/media/engine/images/img_3629.jpg

Some experience with Palasma. In the film, the plasma is formed, even when the current is flowing in the nano-amperes…

And here is video showing that you can do in addition to current, lovely music, which instead of ordinary hum, will be extracted out muffler…

Even serious business, what comes out of mufler treat seriously"

" Designing any exhaust system today is a challenge – especially when it is for an iconic sports car with a famous sound signature. Ricardo’s WAVE software was used by Porsche engineers in the development of the latest 911 model"

Another way of getting electricity from hot exhaust pipes. Termionic generator, such as the electron tube. Current density obtained is about 10 watts of 1 cm square area of ??the outlet pipe

http://fti.neep.wisc.edu/neep602/SPRING00/lecture9.pdf

Of course, the acquisition of the MHD generator, which has electrodes inside…

To assist the electron reactions, a high voltage can be applied, as in TIG welding machines,…

Andrew ![]()

But nothing to prevent the high temperature of the inner cathode acquired using shale gas, or coal.

if we pipe with a radius of 10 cm heated, it will receive its length 1cm, 600 watts, which is enough for the house to its length of 20 cm or 12 KW … …

Extremely small heating stove diameter 20 x 20 cm, and everything we have in the house for electricity, including heating …

In this case, the inner tube should have fins to really depriving heat of combustion.

Andrew: D

Here, such a concept of the new engine to the bicycle. Will definitely help in fast biking, be using any fuel … I wonder how, in practice, this will help … This will definitely help … can at all do not have to pedal? :rolleyes:

http://www.lasaero.com/site/products/article?id=R012B36S5

http://members.eaa.org/home/homebuilders/building/instruments/4A%20Gyro%20Instrument%20System_%20(Your%20Options).html

And all it may seem laughable, were it not for the dimensions of the venturi nozzle, which can this piece of brass with a film about the rate gyro, spin up to 10 000 rpm at 40 km / h …

Of course, I see that freed the next ideas of something we are very happy. Introduced only basis to be developed. Now I am going to have such a number, which encourages the implementation of this idea. Venturi nozzle is one in the figure is the front surface of 3.14 x 2.1 x 2.1 = 13, 8 cm sqare.

6 pieces battery has 6 x13, 8 = 83.0 sqare cm. that is, it is only the surface 8 x 10 cm …

A man riding a bicycle is at least a surface of 50 x 50 cm = 2500 sqare cm. Theory can obscure the surface without loss, for which he will be hidden. So such sixpack can theoretically put 2500/83 = 30 pieces … without magnification face of the rider. So these 180 pieces of brass drums …

Andrew: D

If on the brass cylinder with electric gyro cut the steps for air, we get a full hybrid-electric-air drive …For sure the electric motor would be well-cooled, which contributes to the miniaturization …

Andrew

Teflon burns, with rather toxic results, at way too low a temperature. Somewhere around 250 - 350 C., and that will give off fatal gasses. Even when you’re cooking a stir-fry in a wok. Teflon Woks suck. An engine runs at far higher temperatures. Teflon ain’t going to cut it. You need oil. Teflon ain’t going to do it. It doesn’t even do it in cooking in your wok. Let alone your engine.

The end of such passive sports engine exhausts:

These old-style sausages only reach about 0.2 atmosphere vacuum. A new way of sucking exhaust ejector via a venturi is able to achieve 0.8 atmosphere vacuum. We can add it to the engine power of about 30% if the well will adjust camshaft…

As a result of additional air into the exhaust also added clarity will improve as a result of combustion gases…

The company has also achievements in the treatment of gases, both solid particles and NOx …

For large trucks and marine engines, you can give the water cleaner exhaust. Then, no longer see the black smoke from the exhaust pipe truck. A vacuum is created and injected via a closed loop water will improve engine efficiency as a significant …

Andrew : D

There are any number of concepts for achieving the same basic sequence: intake, compression, ignition, expansion/power extraction, exhaust. The true challenge occurs when you try to execute that concept in real life while meeting a number of design requirements:

-longevity

-efficiency

-low emissions

and tackling the biggest challenges:

-lubrication

-thermal management

-sealing

The Wankel engine for example has high surface-area-to-volume ratio, which means it wastes a lot of heat (=poor thermal efficiency), and also suffers from high hydrocarbon emissions (the flame front quenches when it comes within a certain distance of a surface, leaving a thin layer of unburned mixture; a lot of surface area means a lot of unburned mixture). They also have a difficult time lubrating the apex seals on the rotor, resulting in limited longevity.

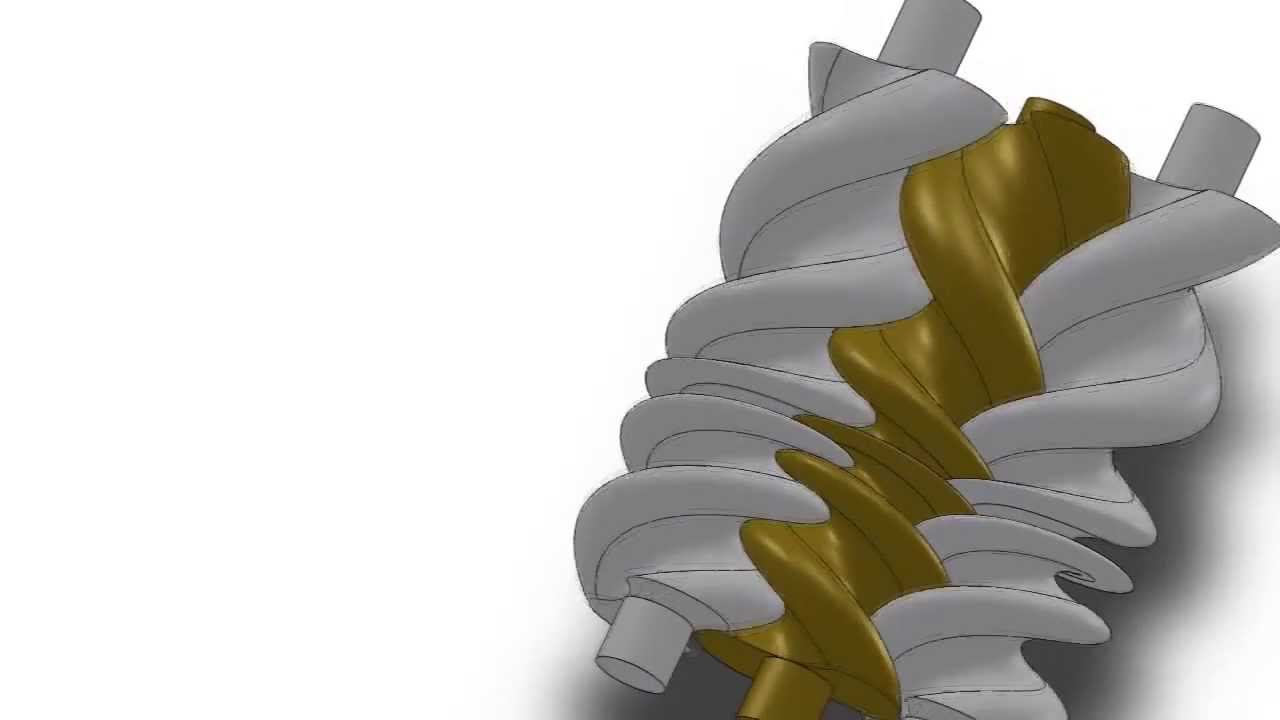

The same problems exist on many other engine concepts. The “corkscrew” engine in your video (very similar to a Roots blower) looks like it would suffer from some of those same issues: lubrication (how do you lubricate the sliding interface between the screws and the housing?), thermal management (how do you cool the screws?), and sealing (how do you effectively seal the sliding interface between the screws and the housing?).

Well, for one, the rotors don’t actually touch each other or the housing, as per the site and general engineering knowledge in the field: only the bearings are lubed.

The main obstacle is how to properly cool the engine: perhaps running coolant through the rotors, but how do you do that?

:dubious:

So the plan is to have the rotors run with a very close clearance fit, over an extremely wide range of temperatures and pressures? In a conventional reciprocating piston engine, the piston/bore interface is a clearance fit, but a piston ring is required in order to achieve a seal. Without the rings, the leaking combustion gases would soon overheat and destroy the surfaces in question - much the same way a conventional engine’s exhaust valve gets rapidly melted/destroyed if it gets held open by a chunk of carbon. I don’t think the Roots-blower engine will last long if there isn’t a positive seal of some sort between the scrolls and the housing to keep blow-by to a minimum.

It is true that the scrolls in a Roots-blower supercharger don’t make contact with each other or with the housing. Leakage is OK in this context, since temps aren’t that high. Combustion is a whole different temperature range.

The engineers will ask this same question. I believe the Wankel does something like that. It’s one more feature that adds cost and reduces reliability. The Wankel works well for a narrow range of applications (racing in particular, where a broad flat torque curve is important, and emissions/longevity aren’t); for everything else, you’ll notice it’s not widely used.

I figure, the engine would be better with separate compressor and expander sections, the latter constructed out of ceramics.

instead of direct drive, the two sections are connected via differential gear: as load is placed on the expander and slows it down, the compressor proportionally speeds up and provides extra boost instantly and continuously.

Again, without a positive seal - especially in the combustion/expansion section - leakage will be problematic. In a conventional piston engine, this leakage of raw fuel/air mixture and combustion products is captured in the crankcase and routed back to the intake (see positive crankcase ventilation). In this Roots-blower engine, blow-by just moves downstream from one chamber to the next, never being separated from the main exhaust stream. It will go out the tailpipe, resulting in extraordinarily high hydrocarbon emissions.

It’s practical aspects like this that prevent a lot of theoretical concepts from being mass-produced.