Automotive dopers: can I get any opinions on this engine design that has four pistons operating in one cylinder? Are there any engines of this type in production today, and if not, why not?

Well it would be very wide.  I suspect that there would be issues with trying to get your manifold runners to be the same length. I also think there might be a greater than normal friction drag due to all the bearings in that engine.

I suspect that there would be issues with trying to get your manifold runners to be the same length. I also think there might be a greater than normal friction drag due to all the bearings in that engine.

I actually posted a link about a modern incarnation of this here once, but danged if I can find it now. The short answer, IIRC, is that it’s not really all that efficient.

There are not, as far as I know. As to why, I can speculate.

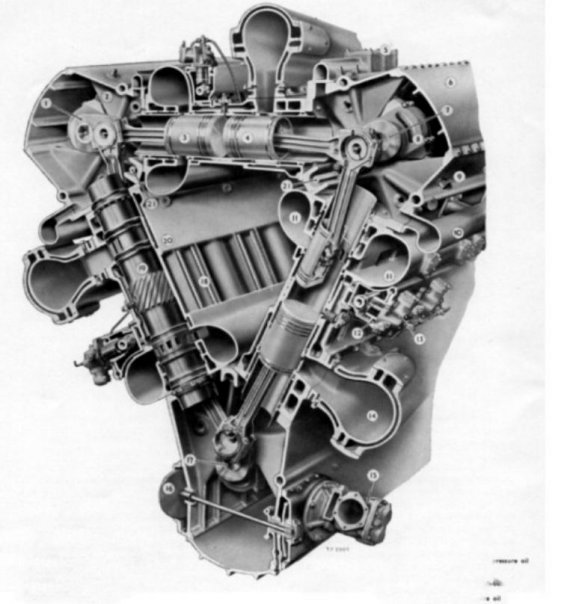

The first thing to notice is that it’s a two-stroke. It uses inlet ports rather than valves, and outlet ports for the centre pistons. The outer two pistons have exhaust valves, two each for some reason.

Now, two-stroke gasoline engines are an abomination since they blow-through with fuel-oil-air mix on every stroke, slinging unburnt gasoline and oil out into the world. Not good for fuel economy, not good for the environment. The only good thing about two-stroke gas engines is that they are simple and cheap to make (no valves, no camshaft), and powerful for their size.

With this design, “simple and cheap” goes out the window. The only advantage to it is power, the power-to-weight and power-to volume should be impressive! But we have better ways now of getting lots of power out a small package - supercharging, designing for high revs, or switching to free-piston engines and gas turbines. And they’d all be cleaner as well.

The design could also be used for a diesel. Two-stroke diesels are great, since they blow-through with nice clean air every stroke! Nothing wasted, no emissions. And something similar has been used in the past. Check out the “Commer knocker”. There’s a nice little animation at the bottom. The blower is to provide blow-through pressure, otherwise known as “scavenging”.

http://www.sa.hillman.org.au/TS3.htm

The Commer knocker hasn’t got the extra two pistons on the outside, which omits the need for valves and camshafts, and so simplifies the design. But in its time it was one of the most advanced diesel engines, giving impressive power-to-weight even by today’s standards.

Diesels are the traditionally heavy power plants, for trucks and boats. Power-to-weight is not normally paramount. So what would a diesel engine of this design be good for? Aircraft?

As it happens, the opposed-piston two stroke diesel has been used for aircraft! Check out the Junkers Jumo 205 (pdf warning!) http://www.enginehistory.org/Diesels/CH4.pdf

Again, it only uses two opposed pistons rather than four. And today, we’d use gas turbines in place of flying diesels. but if someone had developed this four-piston design earlier, before metallurgy made the turbine king of the air, it would probably have been widely adopted as a diesel aircraft engine.

If you like funky engines, this is another opposed piston diesel engine with the pistons arranged in a triangle. The Napier deltic, which is apparently still in service in Royal Navy minesweepers.

Thanks, matt. I guess the inventor was about 10 years too late?

That’s about right! He wasn’t the only one to be overtaken by the turbine revolution. Napier developed a post-war diesel for aircraft that used a turbine to extract more energy from the exhaust, the Napier Nomad:

This is basically half of a gas turbine engine. Instead of having a rotary compressor on the front end and using continuous combustion, they used a diesel engine. The diesel functions as its own reciprocating compressor, and its intermittent combustion means you can make it out of fairly ordinary alloys. It performed superbly for a piston engine… but the new nickel-based superalloys removed the need for intermittent combustion! All that development, all that complexity, and a revolution in materials made it obsolete. The gas turbines that replaced it were less complicated and less ingenious, but they outperformed it.

To nitpick - It was actually a whole gas turbine, coupled to a 2-stoke diesel and in one of it’s modes burned fuel itself like a normal turboshaft

What killed it was its incredible complexity (IIRC the most complex engine ever made because of the need to match two totally different engines with different combustion cycles delivering power to the same shaft)

The Nomad wasn’t made obsolete by the gas turbine, partly because it was one, but mainly because it was trying to achieve a different end to pure turboshaft engines – namely fuel efficiency above everything else.

IIRC that efficiency was achieved, but the extraordinary complexity meant unrealistic weight, size, cost (and I’m guessing reliability, given Napier’s history - they had brilliant ideas like the Sabre and Deltic but were too small to have the resources to make them trouble-free)

I missed that! Thanks. Conflating sources, I’m afraid! I was remembering an old textbook from the 1950’s confidentally stating that the turbo-compounded reciprocating engine was the way of the future. That, and the Allison turbo-compounder being dropped because of the promise shown by gas turbines.