F-18 jet at Spanish air show almost hits crowd in maneuver to avoid bird strikes.

This was a CLOSE one.

F-18 jet at Spanish air show almost hits crowd in maneuver to avoid bird strikes.

This was a CLOSE one.

Lucky!

I love air museums and go to as many as I can. This one is 40 minutes away from me. Why have I never even heard of it? Thanks for the link, it’s added to my list.

I don’t quite follow… Is that a system which is in any way necessary or even useful for safely flying the plane? Or is it the faucet in the economy class bathrooms?

Well, that’s the question isn’t it? What is the intent of the regulation vs the strict application of the words as written.

The regulation reads (bolding mine):

>“Substantiation of satisfactory operation of the aeroplane as a total system, by cold weather testing or by documented evidence of satisfactory operation at low temperature, is required after the aeroplane has experienced a prolonged exposure to ground ambient temperatures equal to or less than -35°C unless an alternative minimum ground ambient temperature has been proposed by the applicant and accepted by the Minister.”

There’s no distinction between types of systems, and their importance with regards to safe flight and landing (the regulation has not been tied to other regulations that do create system criticality definitions).

Then there’s the specific nature of a water system. Even if we accept the regulation applies (the general position from the regulator), what kind of function test can you do in the components at below freezing temperatures if their function requires liquid water? Sure you can show that they may not burst if water freezes, or any burst doesn’t damage critical systems…but then you’re back to the first point.

On the other hand, this sort of testing is critical for, say, fuel and hydraulic systems, but also those things are still liquid at those temperatures.

I’d love to see this criteria be more closely tied to other regulations and take a system criticality approach but getting Transport Canada to engage in new rulemaking is like trying to tame a unicorn. And given as this rule doesn’t exist in the USA or Europe, their usual tactic of waiting for those authorities to change their rule, and then “harmonizing” with them isn’t going to work. So it remains a difficult rule to comply with, with no end in sight.

As said, what matters is that the system doesn’t have pipe or tank bursts while frozen. Or pumps whose electric motors overheat & arc while the impeller is full of ice.

Because “economy bathroom” sink water that ends up leaking all over the inside of the plane can flood electronics compartments, get into control cables and freeze them into immobility, etc. Lots of very dangerous stuff can occur if potable water gets loose in quantity where it doesn’t belong.

Plus the fun of when gray (= “toilet”) water gets loose where it doesn’t belong.

Water systems are also critical to safe flight.

In bizjets, we have to remove the potable water tank when freezing temperatures are expected and hangar space isn’t available. Then install it again before the next flight. One of my least favorite chores - it’s complex enough I think it should be a maintenance action.

My current plane has a procedure allowing us to drain the potable water tank in flight. Easier than physically removing it, but also a somewhat involved undertaking.

It’s not a maintenance action because operators don’t want to pay local MRO to do the work at every airport you land at.

Purging and draining the water system is super important, as is demonstrating where a leak would flow, ensuring it’s routed away from other systems, computers, and routed to drain masts, etc. It’s all super detailed via compliance to 25.1301, 25.1309…regulations that direct a certification approach and criticality assessments etc. Then 525.1301-1 (quoted above) is just a general “whole plane” thing that kind of leads to even stricter interpretation.

@Llama_Llogophile I’m so curious to know which plane you currently fly!

Way back in the dark ages on a 727 I once had a first class lav faucet stick in the flowing position. With the sink drain in the closed position. Whoever used the sink either didn’t notice or just slunk back to their seat without telling anyone.

Lav sinks didn’t (don’t?) have overflow ports like sinks on the ground do. So once the basin’s ~ 1qt capacity was full, the rest flowed onto the lav floor. And from there downwards into the aircraft’s electrical / electronics bay. The tank held IIRC 30 gallons of potable water and most of it was poured into the primitive electronics that controlled the main electrical supply.

Boom! Total irrecoverable AC power failure. It was a nice sunny afternoon, but wow did we snarl traffic into JFK! Fortunately it happened a bit after we’d started descent so the time to landing wasn’t excessive. Also handy that 727s don’t really need much electricity to fly. Computers? We don’ need no steenkin’ computers!

The most recent amendment to the 727 type certificate was in 1991! The regulations have changed a lot since then!

That’s a great example of failure modes that are expected to be addressed now, but that weren’t asked for in the past. It is an ever-evolving landscape but there’s also a tendancy for regulators to address one regulation in isolation without considering how others may be affected (I’ll grant this has improved considerably in recent years).

Both the 727 lav and adjacent galley by design have an impervious rubber layer under the visible flooring and above the not-water-tight aluminum floor. Much as domestic showers are supposed to have a rubber basin above the structural floor but underneath the finished flooring.

The airplane was 20-25 years old when this happened and the rubber layer had developed cracks and gaps. The effort to inspect or correct problems with that layer is wildly disproportionate: remove the lav and galley entire. Fine enough for a D check or a complete cabin replacement/refresh. But certainly not a project for routine line or overnight maintenance.

The materials technology of mostly-not-flammable flexible plastics / elastomers / rubbers has come a long way since the mid 1950s when the main components of the 707 (and hence 727 & 737) were designed.

What happened to the P-8 surveillance plane that ended up in the water at Marine Corps Base Hawaii, Kaneohe is solved. It’s being scrapped after salvage of usable components and systems. It was an ill advised downwind landing toward the bay on a wet runway that contributed.

The P-8A had suffered extensive damage in the mishap, which was compounded further by sitting in salt water for roughly two weeks.

Est. reading time: 5 minutes

Ouch! But about as expected. Thanks for the update.

A darn good question is what components might have been salvageable. I expect it’s rather few.

I still have flash backs trying to land my tiny Schweitzer I-26 sail plane downwind…..the one and only down wind I attempted (was instructed to do so in prep for a 50 km x-country.)

The plane was so small and light I just floated down the length of the runway ( the air brakes are a joke on that plane ) and managed to pull up to circuit and land into the wind. Good lesson.

We had an interesting flight this morning; took off ≈ 20 miles inside of a TFR! The winds were SSW instead of E (epicenter of TFR) so they didn’t even bother to give us a code for the transponder that we were going to use as we weren’t going that way. (Hint: Transponders & ADS-B are only required in aircraft with onboard electrical systems.) We did deal with USSS but that was in the pre-flight frisking, so yes, it was obviously an allowed flight. It was because it was a festival rather than just a private flight. Unfortunately, no flight last night or tonight, but we are/were allowed to stand up for glows. Always fun to break the rules…with permission!

Sounds fun. How far / long were you up?

A darn good question is what components might have been salvageable. I expect it’s rather few.

I don’t know about the aircraft side of this but if the electronics got immersed in salt water it’s toast.

Yeah. And substantially all the dollars are in the military mission avionics. The rest is a dumb 1960s aerial dump truck.

Anything along the bottom; sensors, antennae, wiring, engines, the radome were toast. The aircraft was not submerged completely. There won’t be a list of surviving components. Wild conjecture on my part - workstations and hardware, other stuff above floor level may have been salvaged.

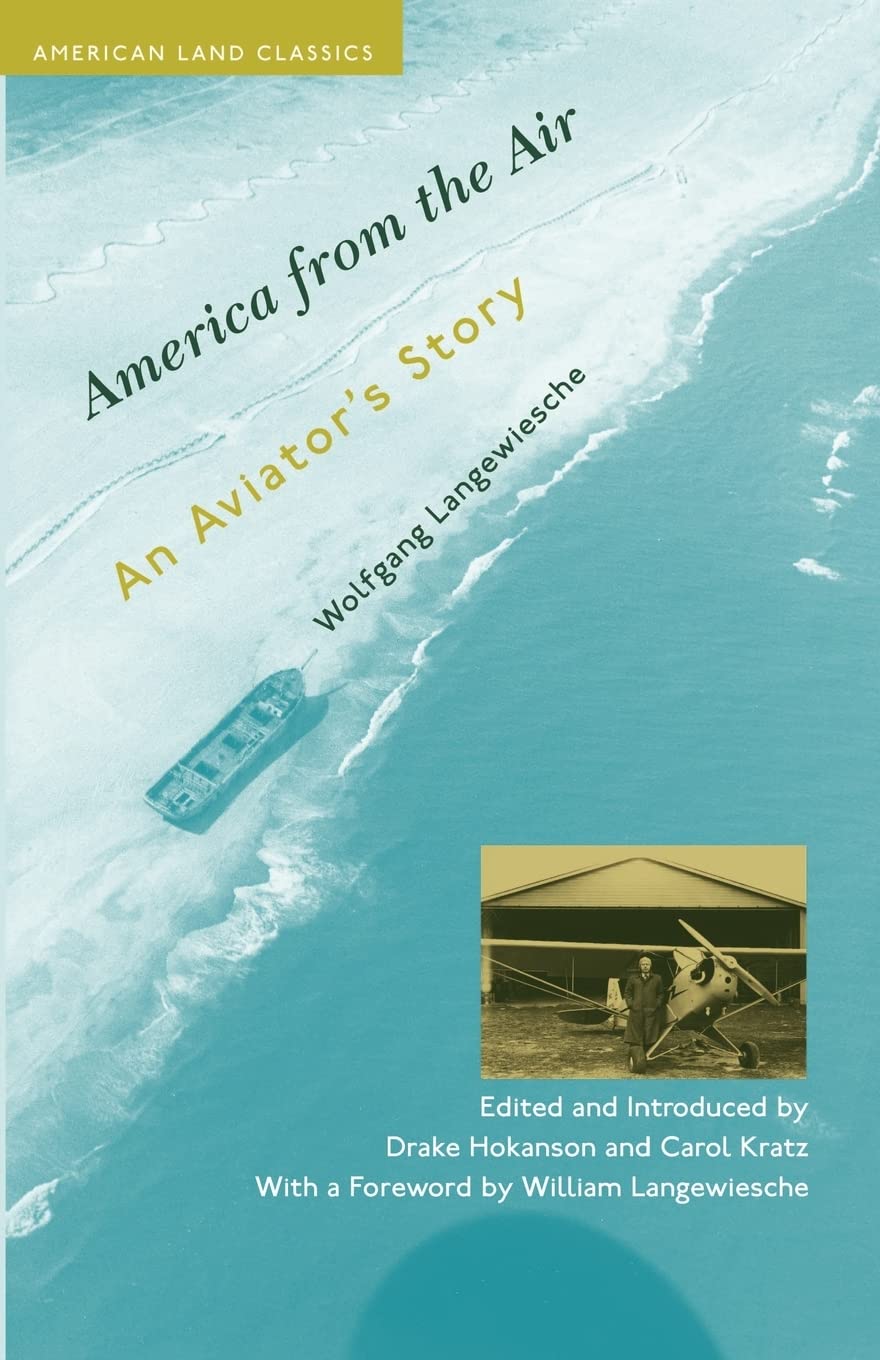

I’m reading this book, edited and introduced by our wonderful neighbors. I just learned that, when you GA folks are talking about a “cross country flight,” you mean anything beyond about 50 miles from your home airport — not, say, from New York to California! Silly me. (This makes a post a few post at up make much more sense).

Carry on…

Amazon.com: America from the Air: An Aviator's Story (American Land Classics): 9780801878190: Langewiesche, Wolfgang, Hokanson, Drake, Kratz, Carol A., Langewiesche, William: Books

$28.17