The barrel, not so much. The firing pin in this example is still metal, and the ammunition, of course. And this is just a dinky zip gun, but the point stands. Plastic barrel, and if you can sneak the nail (firing pin) and rounds through a metal detector, in, say, a rabbit’s foot, the rest of the gun wouldn’t set it off.

It’ll be awhile.

There are no “push-button” 3D printers to date and none of the good ones are cheap. You also need to have a certain degree of 3D drafting skill as unless you have the right file on the right printer there always seems to be an issue, at least in my experiences. You could buy a CNC’d Sherline mill and lathe for less than a high-end 3D printer and make a gun that could shoot hundreds of rounds. Really.

There are a lot more 3D printer enthusiasts right now since various companies have made a bunch of ~$1k printers that can print cool stuff. You just have to make an object in 3D, slice it, download it into the printer, and print. Then you get to watch the magic happen! It’s awesome. I had one and when I finally got it after 30 hours of tweaking it wa sjust awesome. But, these printers require constant calibration and are limited in resolution and max print size.

Also, you can buy a lot of gun parts right now online. It’s the barrel that will provide the forensic evidence and you can buy those readily. Destroying one isn’t that hard either.

Well, you can drill with a mill, but not vice versa. Usually a shop will have a milling machine and a drill press, although nowadays they have fancy multi-axis CNC machines that turn, mill and drill. I don’t believe they can be used for barrel boring or rifling though.

In the US, sure. In Sweden ? Germany ? Ireland ? The UK ? Not so easy to get your dirty mitts on a gun that’s not a sawn-off hunting shotty (and just owning one of those is a ticket to the slammer).

Also, a drill typically only has the Y-Axis of movement. That increases stability which allows you to apply more force if you need too like on hard metals. You can also cut through hard metals with a mill but it will take longer as the column can “flex” so generally you go “slower”. This is all relative to the size of the work piece and the size of the mill.

I know this from experience as I have a benchtop mill and lathe. I thought: “Why do I need my bench top drill press, it’s pointless with a mill!” Nope, I can punch a hole through steel or whatever with much greater speed than a mill. However, the mill is much more precise.

Well, for a lot of nefarious uses of an undetectable weapon, you might not need to get off more than a shot or two (or even any), so durability might not be a huge concern.

The ammo is the big kicker. A plastic gun that you can take through a TSA metal detector undetected is useless unless you have a way of also sneaking those hunks of copper, lead, and brass that the gun needs to be any more dangerous than a camera or a laptop.

In order to accomplish a nefarious plan it would be just as easy to build an explosive/poison gas/chemical bomb which would be more destructive.

A 3D printer can be used to make “plastic” parts or metal parts or wood parts depending on what type of tooling it’s controlling and the software. A 3D printer can be used for goodness or badness depending on the mindset of the operator.

A 3D printer can be used to make a metal gun if one knows anything about casting. Casting is not hard, and easily done in the garage.

It depends on the metal. Aluminum is pretty easy. Brass is harder and cast iron harder still, although people do all three in the home shop.

This article, although heavily influenced by the politics of the news organization and the self-described “crypto-anarchist” appellant, has information on OP. Cites for the law case are lacking.

**DOJ Settles In Landmark Gun Suit, Safeguarding The Second Amendment

**

The age of the downloadable gun is here.

…Due to the terms of the surprising settlement of the United States government, [Cody} Wilson can begin posting his open-source technical data, including files for every gun up to .50 caliber available through commerce, on July 27. An irrevocable content dump, according to Wilson, which renders gun control efforts increasingly futile…

For some context, Wilson first exploded onto the scene with his invention of the Liberator, the world’s first functioning 3D-printed gun named after the iconic WWII weapon intended to arm the disarmed masses. Wilson, then just 25, dropped his open-source gun files online and quickly earned himself the uncomfortable position of being in the crosshairs of the federal government, a position he seemingly intentionally provoked…

I don’t see why a cartridge needs to be metal; only - presumably - the projectile needs mass and solidity. Couldn’t the cartridge be made of paper (aren’t shotgun shells?)

Similarly, the barrel if it likely fails early using less resilient plastic, well, you jut print multiple barrels and swap them out after one or more shots. I assume the usefulness of printed guns, so far, is that they are so cheap they are essentially disposable, like plastic water bottles. This isn’t Dirty Harry, if you need to fire more than a couple of bullets, maybe you really do need a commercially made firearm.

Spinning a cartridge or casting bullets, or producing primers or producing powder are all well within the reach of a modest home shop.

Remember that you are talking about Civil war era technology here. Even if one resorted to milling brass stock a quality small CNC lathe is not that expensive these days.

Ammo does not have a high to manufacture and in fact 3D printers make this whole process more expensive and complicated than it needs to be. It only simplifies current gun enthusiast fashion trends and not function.

Example of a similar operation which is cheaper than a lot of 3D options.

Easy. Just put a single bullet in a rabbit’s foot key chain and casually toss it around the metal detector.

Cite: Some decent-enough movie with Malkovich (bad guy with balsa and rubber band pistol dealio) and Eastwood about a presidential assassin and conflicted secret service guy. Title forgotten.

A lot of good info–historical and current–in The “Carlo”/Carl Gustav-designmachine gun: terrorists/criminals use in US/Europe?

In The Line of Fire.

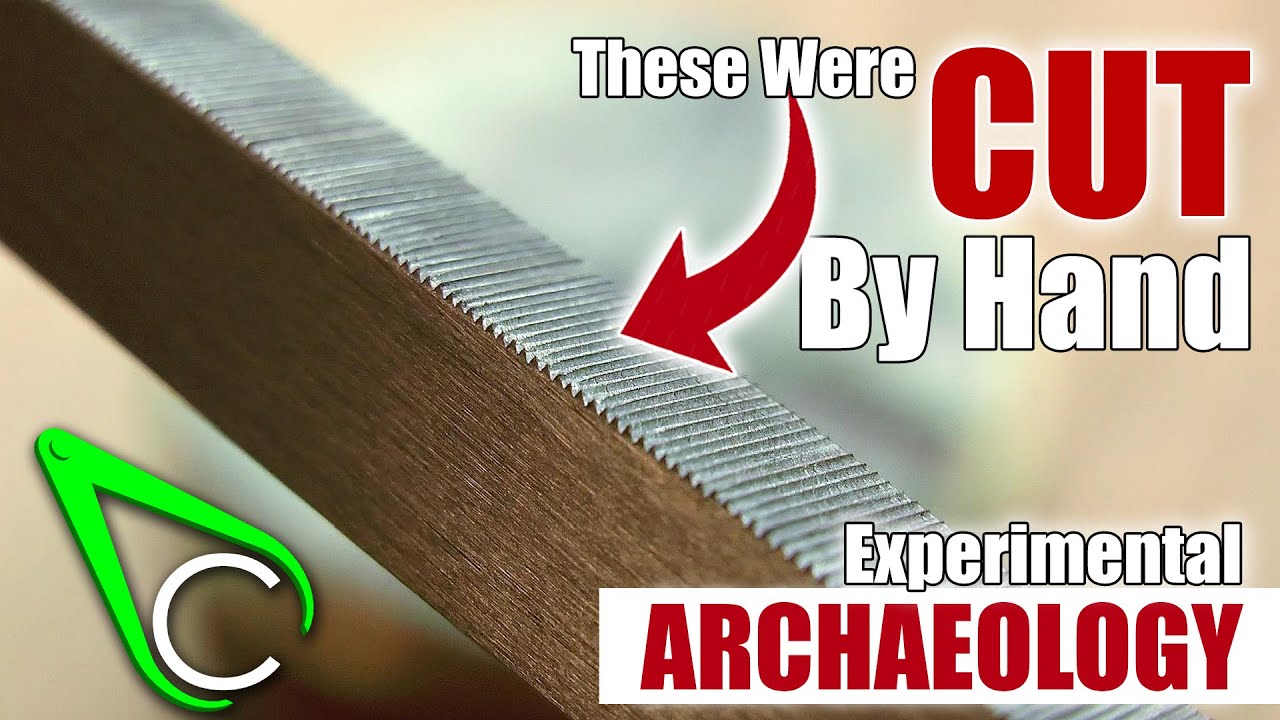

I realize this is an old part of the thread but…No one casts ordnance quality steel alloys at home. And casting is only the beginning, you need to mill, broach, turn, drill, rifle, harden, temper, etc the raw metal parts. And barrels are never made by casting anyway.

Dennis

Consider that the barrel is laying along the top of your dominant hand when it explodes.

To add to this.

Yes cast would be a bad idea but people buy commercial options because of commercial availability at low cost. But if that wasn’t an option it is well within the hobbyist range to work with bar-stock.

Staring with mild steel and using case hardening isn’t that hard. While not gun related but to show how simple it can be.

Remember that the concern is not that individuals would make them but that a black market would be made.

While slightly heavier and pretty dangerous if you have to pay liability insurance even mild steel would work fine and would be workable.

Note I am not talking about color case hardening which is mostly for looks but a lot of ‘trade secrets’ that were held in guilds in the past is available for someone looking to make a market.

The reality is that with 300,000,000+ firearms in the US the fence value of stolen firearms would probably just go up and there would be more burglaries to fit the demand. But a potential black market for illicit firearms wouldn’t need to meet the same consumer pickiness for light weight thin barrels.

I watched a neighbor build a Model 1866 replica as a child, and he used the barrel to show how he was tempering the metal after case hardening, demonstrating the straw to blue transition.

But I also made a 3D printer from absolute scratch, including the circuit boards so that is a bit why I even looked at this thread.

AR15/M16 receivers have a lot of machining steps but an ak47 is very basic and crude.

The only reason that 3D printing makes sense in this case is because it reduces the production time because tool time is far more expensive in this era.

Bump, since the press somehow just got wind and decided to go apeshit GUNS! and noticed the case in my (bump) of #31.

Just saw this, from the ATF, in its entirety:

Does an individual need a license to make a firearm for personal use?

No, a license is not required to make a firearm solely for personal use. However, a license is required to manufacture firearms for sale or distribution. The law prohibits a person from assembling a non–sporting semiautomatic rifle or shotgun from 10 or more imported parts, as well as firearms that cannot be detected by metal detectors or x–ray machines. In addition, the making of an NFA firearm requires a tax payment and advance approval by ATF.

[18 U.S.C. 922(o), (p) and (r); 26 U.S.C. 5822; 27 CFR 478.39, 479.62 and 479.105]