Earlier this week I helped my sister take down and old clothes line. It consisted of two “T” posts with the clothes lines running between.

The “T” posts were metal tubes about 2 1/2 or 3 inches in diameter. Where the cross bar and upright were joined, the upright was cut such that it formed a saddle that conformed to the shape of the cross bar. How is that saddle measured, figured, and cut?

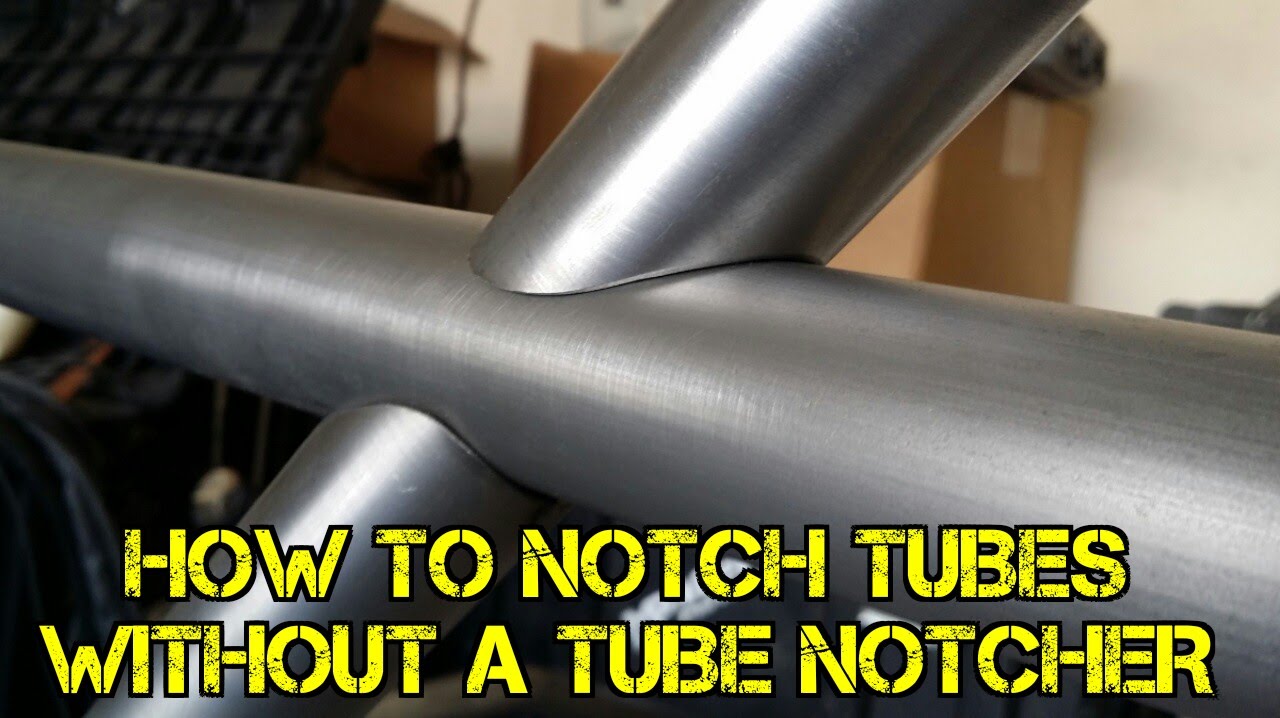

With a tube/pipe notcher and a hole saw with matching diameter. Or, if you prefer to do without, this guy seems to do okay.

I don’t know how that particular assembly was manufactured, but the “saddle” is just a circular cut matching the OD of the other piece of pipe. There are many types of grinding and cutting tools that come in standard circular shapes. I doubt it was ground, but a circular cutter would do the job very quickly. I’m sure they had a standard jig set up so they could just clamp the vertical pipe in place and move it to the cutter (or vice-versa).

Darn! Ninjaed. Of course, I’m thinking of a manufacturing environment emphasizing production and speed.

You can get templates that wrap around the pipe. A skilled fitter can pretty much cut a notch by eyeball and then tune it with a grinder.