My middling physics education did not prepare me for this predicament of adult life: What is the best tool for cutting up corrugated cardboard boxes, and more importantly, why?

Let’s start with your humble box-cutter. You know the kind, cheap plastic thing with scary little blade segments that always threaten to come apart and rip up your garbage bag (or your kids or pets…):

OK, they work, but dull quickly (hence the disposable segments). Why? Something something plant fiber something something cellulose something silica…? I have no idea.

Then you have the ones with ceramic blades:

What’s so special about ceramic for this usage? It’s harder than steel? How does hardness affect cutting ability, physically?

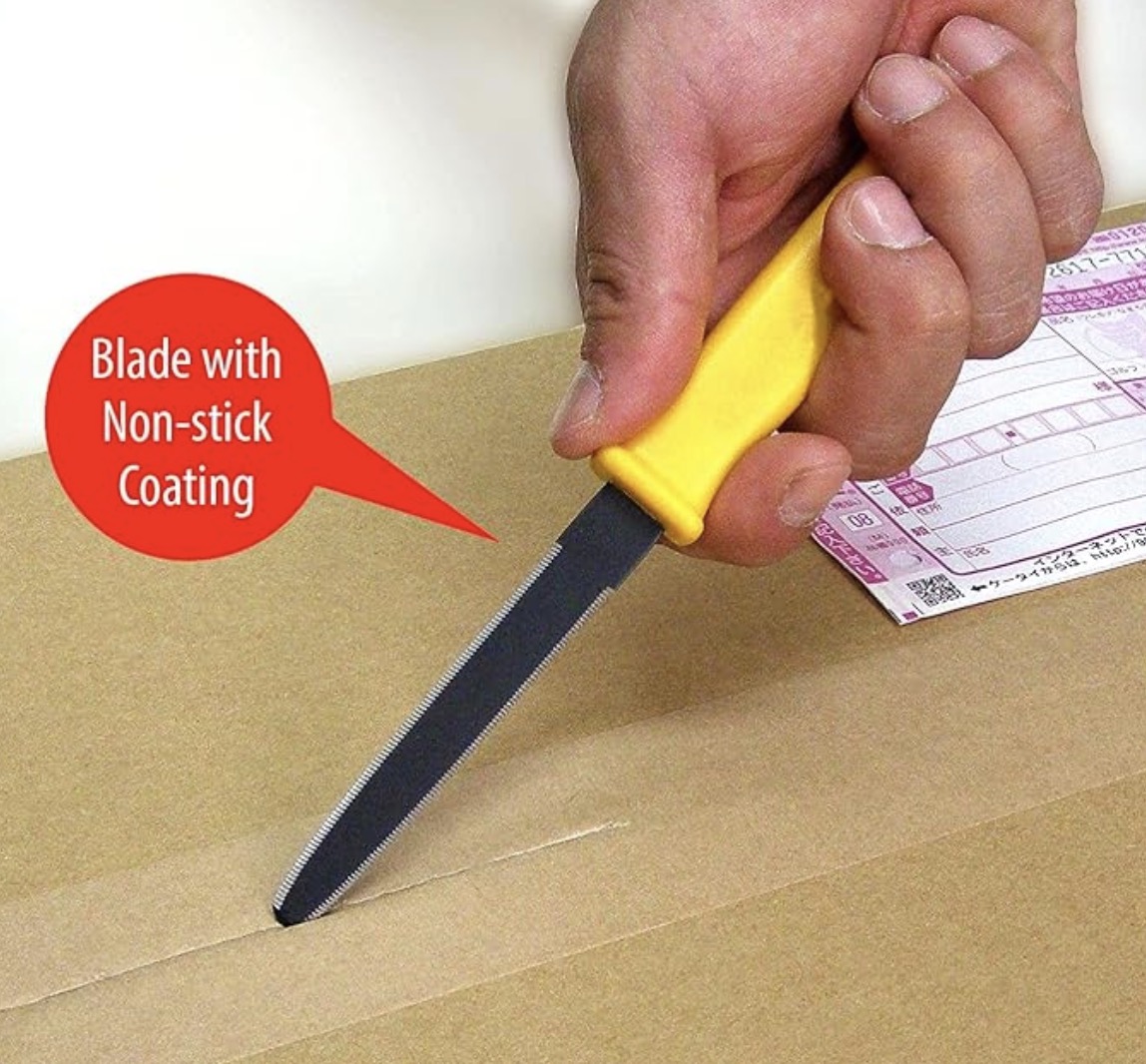

Then you have the samurai letter openers:

Made by the legendary swordsmiths of Japan, then given a serrated edge and teflon-coated. Do the serrations actually help? Why don’t all box cutters have them? Does the coating matter?

That same company also makes special cardboard scissors:

Does that shape confer some particular mechanical advantage against corrugated cardboard?

Speaking of scissors, apparently you can also get electric scissors, though don’t so much cut with and open-and-close motion as much as “sawing” through at a high rate of vibration:

Is that any better or worse than having longer scissor handles/levers? Is there an optimum rate of vibration that can specifically disintegrate cardboard fibers?

But then there’s also the rotary kind, basically a weak rotary cutter with a guard:

Which mechanical motion — a vibrating saw or a rotational cutting disc — works better?

And then there’s the “just for cardboard” premium kind that’s double the price of the other electrics:

That uses a standard utility knife blade and again vibrates it like a saw. It can accept both serrated and straight blades.

Soooo many different kinds. What’s the science behind all this? Is there anyone who’s attempted a systematic study on them to understand (and optimize) all the physical and mechanical forces involved? Are some better for certain kinds of cardboard than others? Is there some curve (or spider/radar graph) between sharpness, durability, ease of use, safety, etc.?