In the old days, you had manual transmissions and automatic transmissions. Manual transmissions had a clutch. When you stopped, you could push in the clutch pedal, and the clutch plate moved back and disconnected the engine from the transmission. You let the pedal out slowly, and the clutch would slip and grab harder and harder as you continued to release the pedal, until the clutch plate was firmly engaged and you had a direct, solid link between the engine and the transmission. Whatever speed the engine was going (RPM), multiply that by the gear ratio in the transmission for whatever gear you were in, and that’s how fast the wheels were spinning. There was no slippage, so it was mechanically very efficient.

Automatic transmissions needed some way to disconnect the engine and the wheels so that the engine wouldn’t stall every time that you stopped. There’s no clutch pedal in an automatic transmission (we’ll leave discussions about automatic clutch transmissions for another day… ahem…) so they used what is called a torque converter instead. You can picture a torque converter as two sets of fan blades that face each other, surrounded by a thick liquid. One “fan blade” (yes I know that’s not the correct term, but it’s descriptive) is connected to the engine, and the other to the wheels. When you stop, the fan blade connected to the wheels stops, but because of the liquid between the fan blades, the engine can still spin. All you end up doing is sloshing around the fluid. No biggie.

But here is the problem. When you make the engine go faster, that makes its fan blade spin faster, which sloshes the fluid around faster, which puts more pressure on the wheels to turn, and off you go. But you never have a solid connection between the engine and the wheels. There is always this fluid sloshing around in between. So you lose a lot of energy to sloshing fluid around.

This is why manual transmissions always gave you better gas mileage and efficiency in the old days.

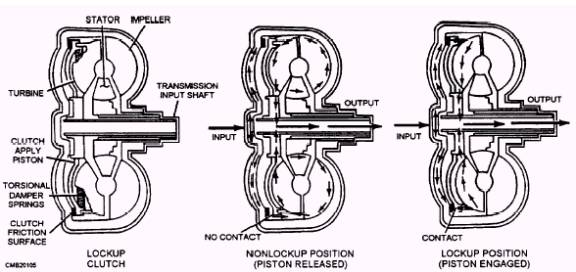

Modern cars fix this issue by having what is called a lock-up torque converter. This functions like an ordinary torque converter when you stop. Fluid sloshes around and lets the wheels stop but the engine can keep going, so the engine doesn’t stall. But once you get going and are cruising down the road, the torque converter locks the two fan blades together and makes a solid connection between the engine and the wheels, so you no longer waste energy sloshing fluid around.

When you stop, the torque converter unlocks, and you slosh fluid around again so that you can stop again without stalling.

So what does all of this have to do with the OP?

Well, if you are driving a really old automatic car, the engine will rev up, but the car won’t immediately accelerate. This is because you are sloshing fluid around and wasting energy. Eventually the extra pressure from the fluid sloshing around faster makes the wheels turn faster and the car accelerates.

But if you have a modern car with a modern lock-up torque converter, and you GENTLY press on the gas pedal, the engine and the car will speed up at the same rate, because the torque converter is still locked.

However, if you’re not so gentle, the engine computer will tell the transmission that it needs to shift, the transmission will shift down into a lower gear, and the torque converter will unlock to allow some slippage between the engine and the wheels until the car gets up to speed. The engine RPMs go up much more quickly, but the car can’t accelerate that fast so you’re sloshing around fluid in the torque converter, but you don’t have a sudden thump and jerk like you would get if you were in a manual car and you shifted gears and just immediately popped the clutch out. Once things stabilize, the torque converter locks up again, because you don’t want to waste energy sloshing fluid around, and then at that point you are back to having a solid connection between the engine and the wheels, and your mechanical efficiency is good again.

So that is where your lag comes from. The torque converter unlocks, the transmission shifts, there’s some lag due to the mechanical inefficiency of transferring power through the liquid coupling of the torque converter, then when things settle the torque converter locks back up and you’re all good.

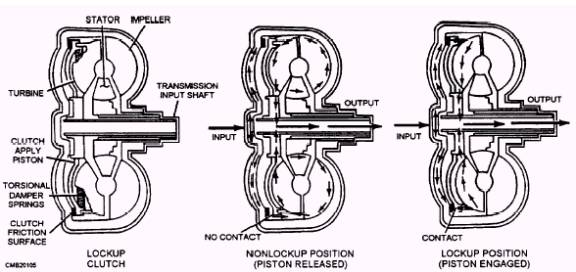

This is what a torque converter looks like inside:

The lockup mechanism makes a modern torque converter a bit more complicated (actual designs vary, this is just the first decent image I could find):