My house was built in 1984. It has copper wiring. We bought the place in 2001 and have been living here ever since.

From time-to-time, I find it necessary to replace an electrical outlet due to wear. The outlet simply won’t hold anything plugged into it. While I am no electrician, I am fine with installing light fixtures or replacing switches and outlets.

My questions:

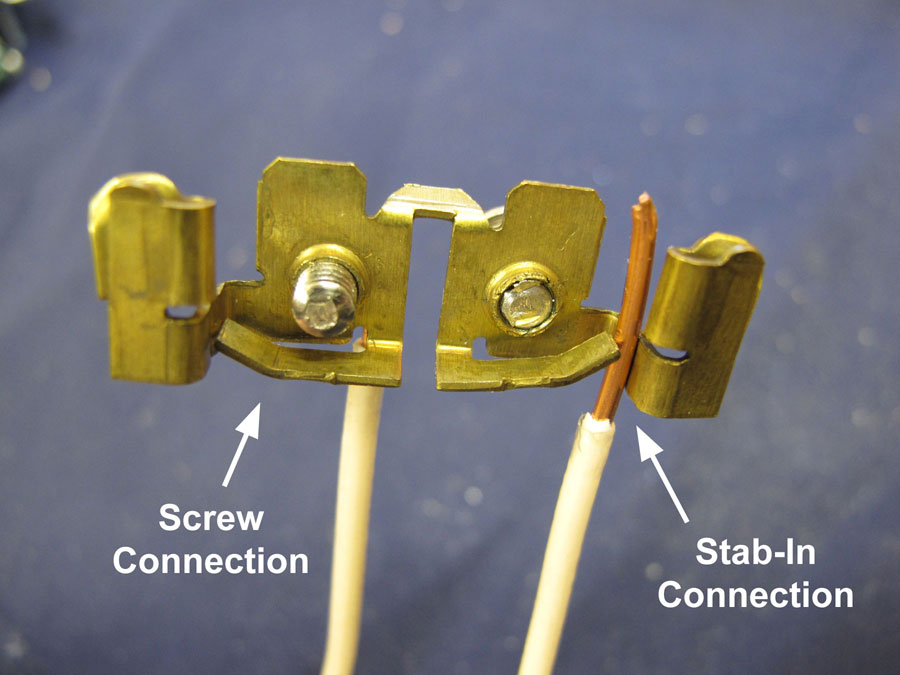

- Without fail, I have found the original outlet to be wired by using the holes on the back. Does this indicate that the original electrician was prone to cutting corners? I install outlets and switches using the screw terminals on the sides with a clockwise hook. The wire cannot work its way out of that.

- All of the outlets I have worked on have had two black wires and two white wires (and a bare ground). One of the outlets I replaced today had only one of each wire. Is that okay? Why would this one outlet be like that? The outlet seems to work fine with just the one pair.

- Any time I am working in a utility box, the hardest part is getting all the wiring back in the box. Any advice on how to stuff everything back in there? On one outlet I replaced today, I just couldn’t get it all back in. The face plate is not flush with the wall, leaving the neutral side slightly exposed. I don’t like this. It doesn’t look good and it strikes me as slightly dangerous.

Thank you for any advice y’all may have.